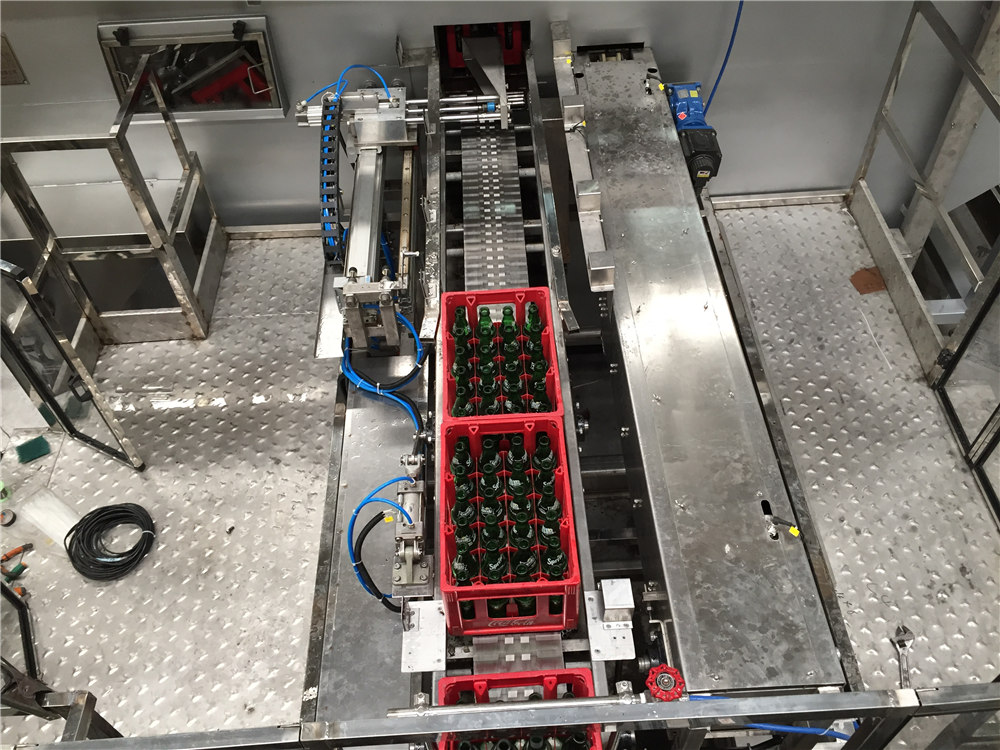

Recycle Bottle – Case Ultrasonic Washing Machine

Video

Description

All recycled glass bottles and containers currently on the market are cleaned separately after the bottle and container are separated. To a large extent, this wastes energy and reduces efficiency. To solve this problem, GEM-TEC designed and invented the bottle and case integrated cleaning machine, the bottle and case together into the machine for cleaning. At the same time, we will clean steel parts, semiconductor devices, eye lenses used in the ultrasonic cleaning machine used in this machine, which undoubtedly greatly improve the cleaning efficiency. The machine was first used in Nanjing Zhongcui Coca-Cola Co., LTD. The company won the "Golden Can" award from the American Cola Headquarters for the machine.

The principle of ultrasonic cleaning is that the high-frequency oscillation signal issued by the ultrasonic generator is converted into high-frequency mechanical oscillation through the transducer and transmitted to the medium. The forward radiation of the ultrasonic wave in the cleaning solvent is dense and dense in the cleaning liquid, so that the liquid flows and generates tens of thousands of tiny bubbles. The tiny bubbles in the liquid (cavitation core) vibrate under the action of the sound field. When the sound pressure reaches a certain value, the bubble grows rapidly, and then closes suddenly. When the bubble closes, the shock wave is generated, and thousands of atmospheric pressure are generated around it, which destroys the insoluble dirt and makes them dispersed in the cleaning solution. When the group particles are coated with oil and adhered to the surface of the cleaning part, the oil is emulsified and the solid particles are separated, so as to achieve the purpose of cleaning part surface purification.

Bottle and box integrated cleaning machine is to input the bottle and box together into the cleaning machine. After a journey of 200s, the bottle and box are cleaned and sent out to enter the next link.

Features

1. Empty box cleaning effect is obvious, more than the existing single box washing machine cleaning effect, improve the product quality image;

2. 90% of the dirt is left in the machine to avoid being brought to the bottle washing machine and box washing machine in the subsequent workshop, greatly improving the sanitary environment in the workshop;

3. It also has a good pre-cleaning effect on empty bottles, which can remove dust, clean dry stains in advance or soak them, and improve the cleaning effect of the bottle washing machine;

4. Can be empty bottles, empty boxes of foreign stains, sediment, dust, insects and accessories (cigarette butts, straws, etc.) in the pre-washing place to remove in advance, to ensure the production line clean, reduce pollution, ensure the bottle washing machine pre-washing and final washing effect, to ensure the lye cleaning and cleaning disinfection effect.

5. Due to the on-line series relationship with the production line, it can be close to a pre-washing of empty bottles, without the need to open a separate production line for pre-washing, saving energy consumption and working hours.

6. The use of bottle washing machine to recover water, no new water consumption, and the recovery of water has a certain temperature and residual alkali.

7. Regular discharge, dirty convenient to be cleaned.

8. It has a breakthrough value for the quality improvement of recycled bottle production.

Production Capacity

1000 -- 2000 cases /H, OR 24,000 bottles -- 48,000 bottles /H