-

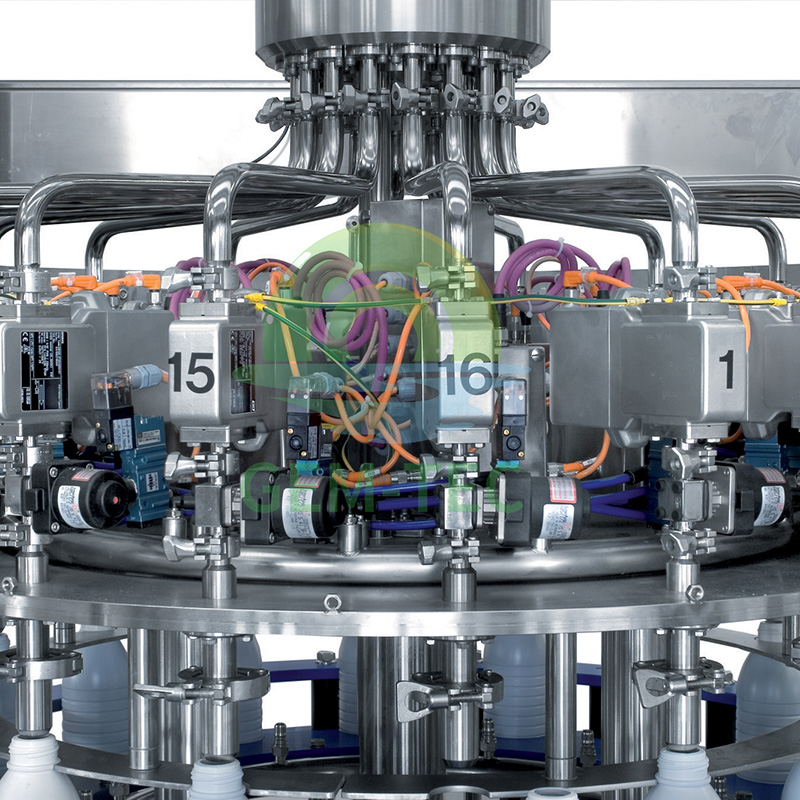

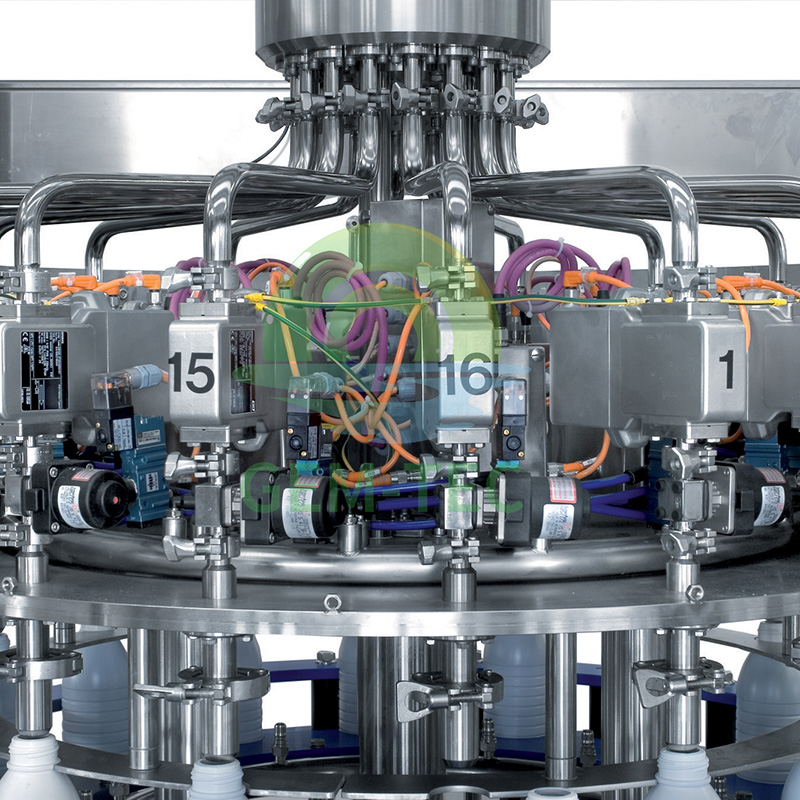

Automatic-semi-automatic CIP Plant for Beverage System

CIP equipment uses a variety of cleaning detergents and hot and cold water to clean various storage tanks or filling systems. CIP equipment must remove mineral and biological residues, as well as other dirt and bacteria, and finally sterilize and disinfect equipment components.

-

Automatic Glass Bottle Wine/ Whisky Liquor Filling Machine

Spirits are alcoholic drinks that are distilled without fermentation. Distilled spirits tend to have a high average percentage alcohol by volume, ranging from about 20% to 90%ABV. To make a strong spirit, raw materials such as fruits, potatoes and grains are used in the distillation process. Common distilled alcoholic drinks are whiskey, gin and vodka. The global alcoholic beverage market is expected to reach about $2 trillion by 2025, the study said. Spirits will account for about a third of the total market. Visible, spirits account for a large share of the market.

-

Bottle Milk-yogurt Beverage Filling Machine

Milk is rich in nutrition elements, can provide the human body with a variety of proteins and active peptides, supplement the human body calcium, is an indispensable drink in People’s Daily life. In recent years, demand for milk and dairy products in various countries has been growing as incomes rise, populations grow, urbanization and diets change. The variety of dairy products varies greatly from place to place due to factors such as dietary habits, available milk processing techniques, market demand, and social and cultural environment. At GEM-TEC, we help you achieve the highest quality and safety of dairy products through our complete low temperature fresh milk, milk beverage, yogurt filling production line solutions. We have developed different process requirements for different dairy products (e.g., pasteurized milk, flavored dairy drinks, drinkable yogurts, probiotics and milk drinks with specific healthy functional ingredients), as well as different nutritional components.

-

Automatic Small 3-5 Gallon Filling Machine

Industrialization and urbanization have concentrated populations, a process that has led to a huge increase in demand for bottled water. Whether it’s water or carbonated water. Health consciousness is also driving strong growth in low-calorie flavored and functional bottled water. With no calories or sweeteners, water is a smart alternative to sugary drinks. Whether at home or in the office, large buckets of water can provide us with larger, healthier drinking water. The water can supplement the light mixture of minerals for a refreshing taste, or it can be pure and clean water.

-

High Speed Carbonated Drink Mixing Machine

Water and carbonated soft drinks remain the two most valuable beverage categories in the world. In order to meet the demand of carbonation, we designed and developed the JH-CH type high speed carbonated beverage mixer. It can more efficiently mix syrup, water and CO2 in a set ratio (within the range of conditions) to produce the effect of water into soda.

-

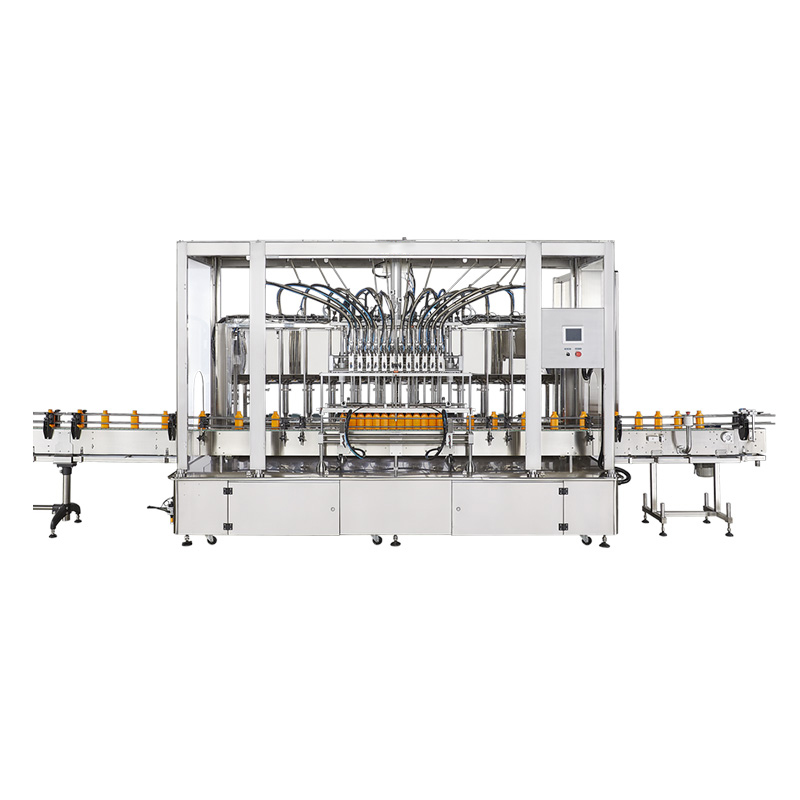

Automatic Small Linear Filling Machine

Linear filling machines are the most versatile and can fill almost any fluid. It is especially suitable for filling requirements with output within 2000BPH. According to the filling requirements of different products, we provide users with different types of linear filling machines. Used in food and beverage (water, beer, carbonated beverages, fruit juices, sports drinks, spirits, etc.), pharmaceuticals, pesticides, breweries, cosmetics, toiletries, personal care, chemicals, petroleum and other industries. The wide range of applications of linear filling machine determines its filling methods are also various, such as piston syringe, flowmeter, vacuum, gear pump, gravity filling and so on. Of course, there are many ways to cover it, such as: gland, screw cap. Corresponding LIDS can be plastic LIDS, crown LIDS, aluminum LIDS, pump head LIDS, etc.

-

Filling Machine for Daily Chemical Products

Daily chemical products are closely related to our daily life. With the growth of economy and the improvement of people’s living standard, the market scale of daily chemical industry is getting bigger and bigger. Daily chemical products mainly include washing products and oral care products and so on. As a more traditional industry, the product categories of daily chemical products industry are complex, such as laundry detergent, dish soap, shampoo, disinfectant and conditioner, etc. The bottles and caps of these products are often varied and irregular, with different packaging containers; At the same time, there are many technical difficulties in product filling such as bubbling, wire drawing and dripping; Filling accuracy and hygiene requirements are also very demanding; Production capacity is also a new trend for filling equipment to put forward new requirements.

-

Automatic Digital Weight Edible Oil Filling Machine

Filling of oil products, including edible oil and industrial oil. Edible oil is the pillar industry of the national economy, is one of the main diets in our daily life, such as peanut oil, palm oil, blended oil and so on. Industrial oil is mainly lubricating oil, in the high degree of industrial automation today, all kinds of mechanical equipment can not work without lubrication, very wide range of uses.

-

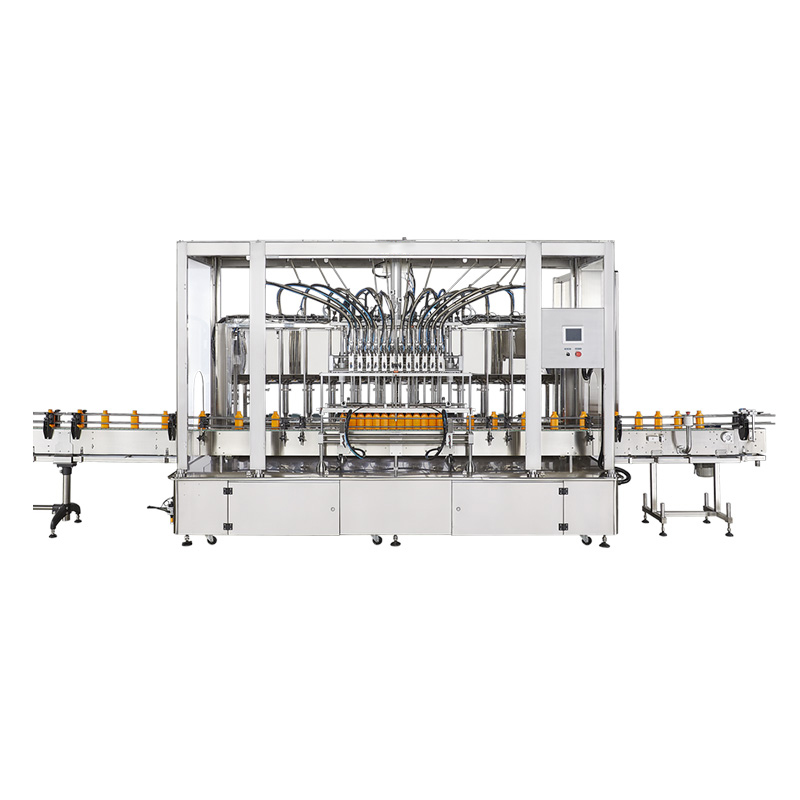

Automatic Bottle Condiments Filling Machine

Delicious food needs seasoning to taste it, after cooking, seasoning to make food greatly improve the quality of our lives. Condiments can be divided into liquid condiments and sauce condiments according to the product form. Common condiments include soy sauce, cooking wine, vinegar, sugar water and so on. Because most condiments contain high sugar or salt content, the filling equipment has high anti-corrosion performance requirements. In the filling process, it is also necessary to solve the problems of bubbling and dripping. At the same time, it is particularly important to ensure the accurate filling quantity.

-

Bottle Feeding Turntable/ Bottle Collector

Bottle Feeding Turntable is suitable for production line with output less than 5000BPH. In production, you only need to place the bottle on the rotary table, which will automatically transfer the bottle into the conveyor belt. Bottle Collector is just the opposite of that of Bottle Feeding Turntable. It collects the bottles brought from the linear conveyor onto the turntable for the convenience of centralized operation.

-

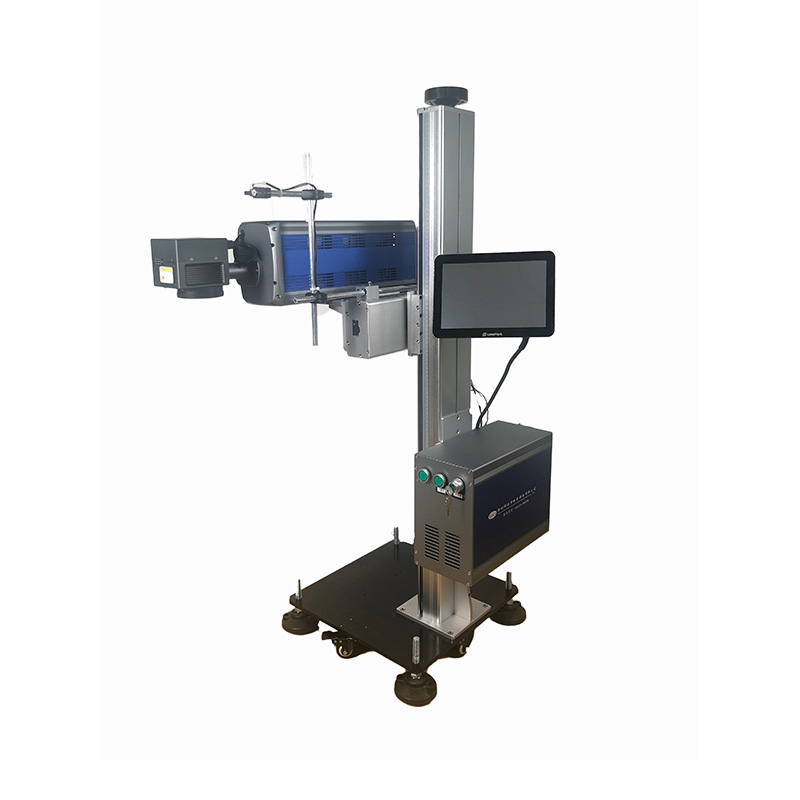

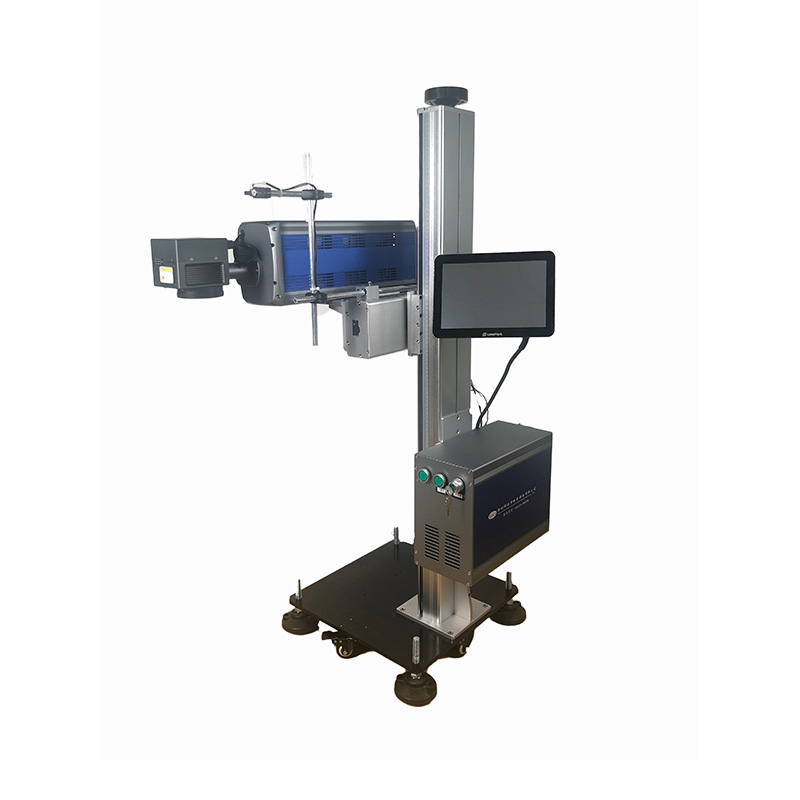

Automatic Bottle/ Can Laser Coding Machine

The computer control system includes a computer and a digital galvanometer card, and the driving optical system component emits a pulsed laser according to the parameter action set by the marking control software, thereby precisely etching the content to be marked on the surface of the processed object.