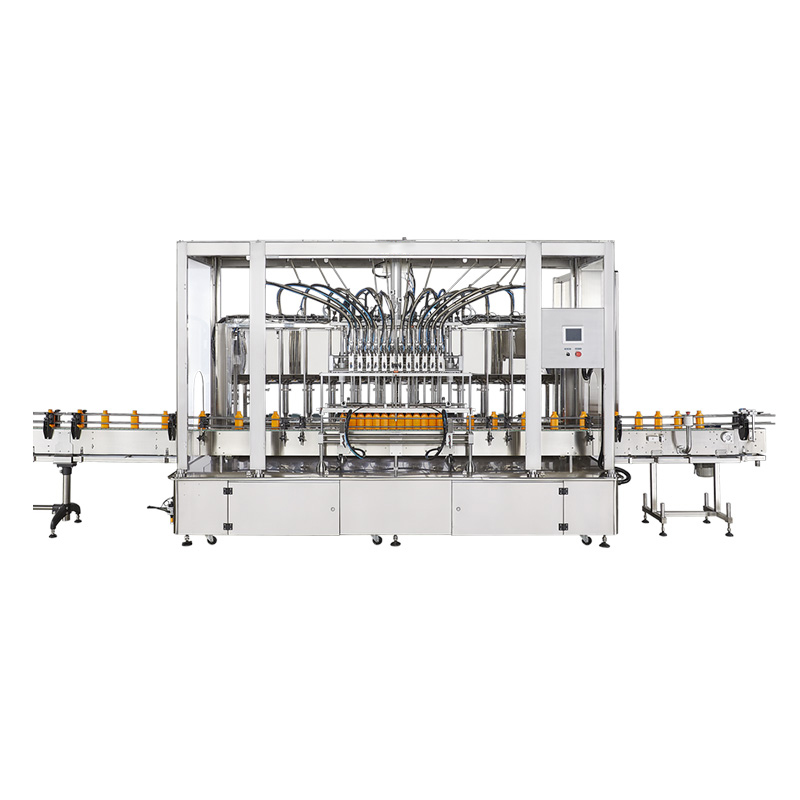

Pasteurization Machine / Warm Bottle Machine / Cold Bottle Machine

Description

Sterilization machine is one of the important machines in beer filling production line. Its main function is to kill the yeast in beer and extend the shelf life of beer. The index to measure the bactericidal effect is the PU value, and the PU value will directly affect the flavor of beer.

In addition to sterilization, the model is suitable for sterilization and cooling of wine, fruit juice and energy drinks, as well as warm bottles of carbonated beverages. We will optimize the design according to the customer's product and production capacity, sterilization temperature, sterilization time, distribution temperature and cooling time.

Main Structure

The main structure of the machine is composed of a tunnel frame and a bottom tank. Most of its materials are made of stainless steel. The tunnel frame is composed of three types: entrance, middle and outlet, which is responsible for conveying and spraying bottle wine. The bottom tank is an integrated structure, which is mainly used to adjust and distribute the spray water in each temperature zone, so as to meet the working requirements with reasonable water temperature and quantity.

1. Frame Part:

The design of the frame adopts modular design, which is divided into three types: entrance, middle and exit. The middle frame is made into the same form of structure, which is convenient for design, manufacturing and assembly. The outlet is equipped with a motor to drive the movement of the chain network. The chain network adopts the traditional sterilizer's diffused stainless steel, and increases the side plate to prevent deviation, so that the operation is more stable, the failure rate is further reduced. The spray system adopts the top leak hole spray, the water is uniform, the cover of the bottle without dead zone, easy to clean. The top cover is water sealed to prevent most water vapor from escaping. Both sides of the frame are provided with side doors for observation and maintenance.

2. Water Tank:

This machine adopts bottom trough type water tank design. The inside of the water tank is mainly divided into small water tank and buffer tank two parts: the small water tank is divided into 10 parts, respectively corresponding to the collection and supply of 10 temperature areas of spray water; The buffer tank is divided into three parts -- the cold buffer tank, the hot buffer tank and the pre-buffer tank, which are used to store and supply water at different temperatures respectively. The cold buffer tank and the pre-buffer tank are connected through the balance pipe, and the hot buffer tank and the pre-buffer tank can also supplement water to each other, to ensure the water level balance of each tank. During operation, the water in the small water tank in each temperature area is used for spraying in each temperature area, and the water in the small water tank is collected and filled and automatically overflows to the corresponding buffer tank for storage. The hot water in the hot buffer tank mainly provides the heat of spray water in each temperature zone, and through the pneumatic V-valve with PID function to adjust the mixing ratio of hot and cold water to make the spray water reach the set working temperature; The cold water in the cold buffer tank is mainly used to provide cold water cooling and to adjust the spray water temperature in the heating and cooling zones when the PU value is controlled.

The water tank is designed with automatic in addition to the broken glass device, in the spray water into the tank before the design of a chain mesh from the head to the tail intermittent automatic operation to catch the broken glass produced by the broken bottle and out of the machine, prevent the broken glass into the water tank, not only protect the valve and water pump and other parts, but also improve the degree of automation of the machine.

Features

1. The whole machine is made of stainless steel, and the chain net is made of high temperature resistant plastic chain net (imported or domestic can be selected).

2. The main drive is driven by large torque and low speed reducer, and the main machine and the in-and-out bottle conveying system are regulated by frequency converter, with low power consumption, stable, safe and reliable operation.

3. The temperature control system is composed of heat exchanger, temperature sensor, temperature controller, pressure reducing valve and pneumatic film regulating valve, the temperature accurately reaches the requirement of ±1℃, to ensure the quality of sterilization.

4. The machine is divided into six or eight different temperature zones, which are equipped with independent circulating water system. The overflow water is collected and recycled by plate heat exchanger, which greatly reduces the water consumption and steam consumption of the sterilizer.

5. The nozzle on the spray pipe adopts a new structure of stainless steel, so that the water is umbrell-shaped mist spray, heating effect is good, there is no temperature dead Angle, heating effect is uniform, so as to ensure the sterilization effect of each bottle.