-

No Pressure Conveying System

No pressure conveying system, as the name implies, is the transition from multiple rows of bottles to single rows of bottles without a little pressure, from multiple rows to single rows of bottles conveying machine only one side guard, bottle conveying through the specially designed differential bottle conveying frame and guard, by the program controller and frequency converter automatic speed to complete, if there is pouring bottle can automatically enter the bottle bucket without bottle blocking bottle, Beverage machinery industry is mainly used in the conveying system of multi-channel change single channel, single channel to bottle inspection machine, bottle inspection machine to wine machine or multi-channel change single channel into labeling machine, etc.

-

Cap Elevator-cap Washing Tunnel

Cap conveying machine is a conveying system for different types of bottle caps in beer and beverage industry. It is composed of storage bucket, conveying part, transmission part, tensioning (deviation adjusting) device and electrical control.

-

Bottle & Box Devider & Combiner

Capacity: 6000-30000BPH

Suitable bottle shape: round bottle (diameter 60cm-95cm), square bottle.

Lane separation: 2~6 lanes

Bottle spacing: 25-40 bottles

Front and rear travel: 500cm

Left and right displacement: 60-100 (cm) -

Bottle Feeding Turntable/ Bottle Collector

Bottle Feeding Turntable is suitable for production line with output less than 5000BPH. In production, you only need to place the bottle on the rotary table, which will automatically transfer the bottle into the conveyor belt. Bottle Collector is just the opposite of that of Bottle Feeding Turntable. It collects the bottles brought from the linear conveyor onto the turntable for the convenience of centralized operation.

-

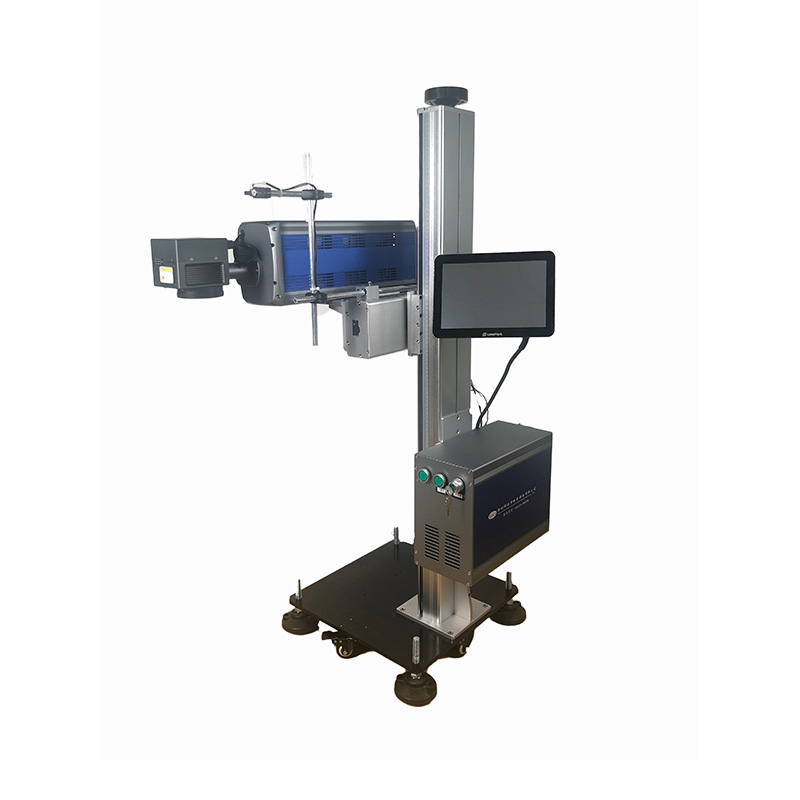

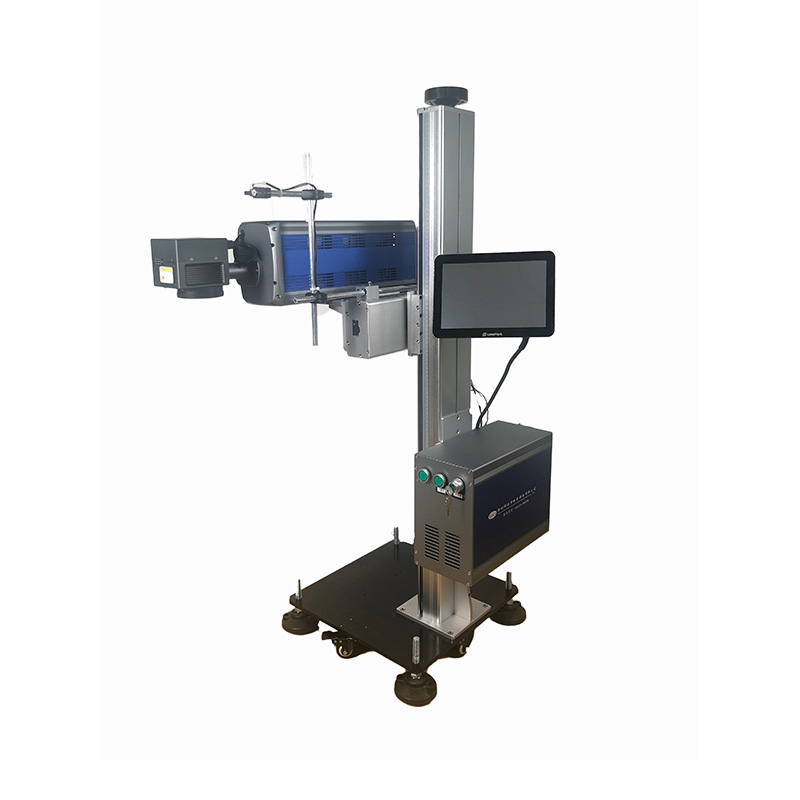

Automatic Bottle/ Can Laser Coding Machine

The computer control system includes a computer and a digital galvanometer card, and the driving optical system component emits a pulsed laser according to the parameter action set by the marking control software, thereby precisely etching the content to be marked on the surface of the processed object.