Automatic Digital Weight Edible Oil Filling Machine

Description

Description

Filling of oil products, including edible oil and industrial oil. Edible oil is the pillar industry of the national economy, is one of the main diets in our daily life, such as peanut oil, palm oil, blended oil and so on. Industrial oil is mainly lubricating oil, in the high degree of industrial automation today, all kinds of mechanical equipment can not work without lubrication, very wide range of uses.

The filling of oil products requires high filling accuracy and sanitary conditions, which is easy to adhere to the surface of parts and cause dripping. In order to solve these problems, GEM oil filling machine not only guarantees the filling requirements, but also optimizes the problems of easy leakage.

Due to the relatively high viscosity of oil products, the use of conventional mechanical valves will cause blockage of the return pipe, so the oil filling machine usually adopts the plunger quantitative filling method. The principle of plunger quantitative filling method is that the material in the measuring cylinder, filling cylinder, filling bottle three containers constantly switch, flow. The valve body is equivalent to a three-way valve. When the valve is closed, the cylinder and the cylinder are connected, and the material is sucked into the cylinder by the piston. The stroke of the piston determines the volume of the material being sucked, thus determining the volume of the material being filled. When the valve is opened, the cylinder and the bottle are connected, and the material sucked into the cylinder is pressed out into the bottle to complete the quantitative filling process. Since the filling capacity can be changed by adjusting the piston stroke, it is easy to fill bottles of different capacities. In addition, the part that controls the piston can be replaced by a servo drive, which makes the filling more accurate and the capacity more convenient.

With the exception of plunger filling, most oil filling machines use weigh filling technology. After the empty weight of the container is determined, the filling valve is opened when the bottle is detected. During filling, a weighing sensor detects the amount of product injected. Once the required weight is reached, the valve closes immediately. After a short resting period, recheck the weight. Just before reaching the bottle wheel, the valve is raised again to ensure that the bottle leaves the machine cleanly. This filling method can be customized with automatic CIP function, cleaning fake cup automatically mounted, CIP does not need manual operation.

Technical Structure Features

1. Conventional filling using plunger quantitative filling, filling accuracy is high, easy to change. Electronic weighing/electromagnetic flowmeter filling valve is used for products with high capacity requirements. No matter what kind of filling valve can effectively prevent valve orifice dripping.

2. Siemens control system is adopted, with high automatic control ability, all parts of the function is fully automatic operation, no operation is required after starting up (for example: filling speed follows the whole line speed, liquid level detection, liquid intake regulation, lubrication system, bottle cap conveying system)

3. The machine transmission adopts modular design, frequency conversion stepless speed regulation, wide range of speed regulation. The drive is equipped with automatic lubricating grease device, which can supply oil to each lubricating point according to the need of timing and quantity, with sufficient lubrication, high efficiency, low noise and long service life.

4. The height of the material in the filling cylinder is detected by the electronic probe, and the PLC closed-loop PID control ensures stable liquid level and reliable filling.

5. According to the requirements of different products, filling method and sealing type can be matched at will. Various sealing methods are available (e.g., plastic gland, plastic thread cap, etc.)

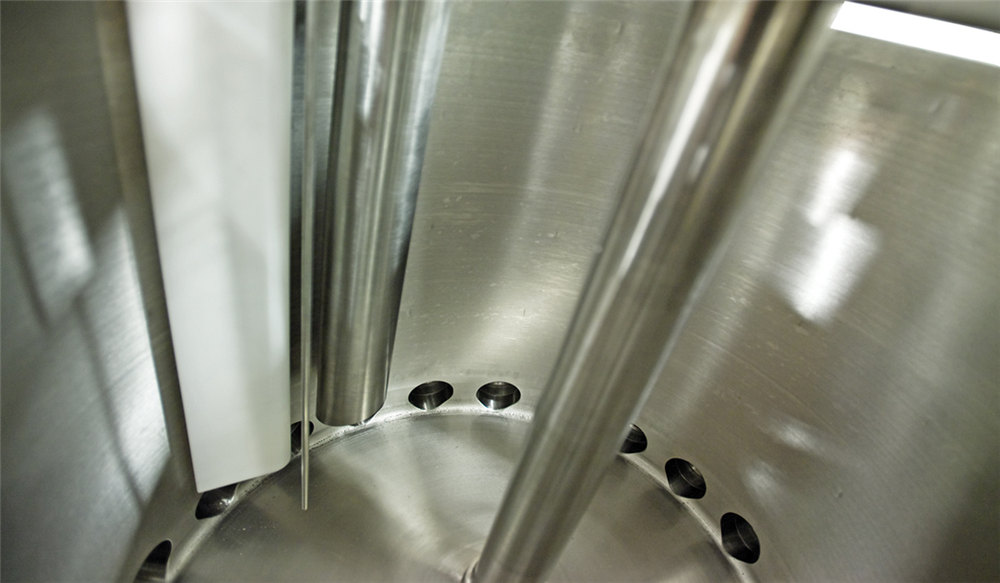

6. The material channel can be cleaned CIP completely, and the workbench and the contact part of the bottle can be washed directly, which meets the sanitary requirements of filling; Can be used according to the need of single-sided tilt table; Custom automatic CIP fake cups are also available.

7. No contact between bottle and filling valve during filling to avoid cross contamination.

Structure

Parameter

|

No. |

Model Series |

Material Viscosity range CPS |

power |

Equipped with air source |

Equipped with power source |

Conveying line height

|

suitable for bottle type range |

|

01 |

JH-OF-6 |

0-200 |

3Kw |

5-6bar |

380V |

1000±50mm |

Customized according to customer needs

|

|

02 |

JH-OF-8 |

0-200 |

3Kw |

5-6bar |

380V |

1000±50mm |

|

|

03 |

JH-OF-10 |

0-200 |

3.5KW |

5-6bar |

380V |

1000±50mm |

|

|

04 |

JH-OF-12 |

0-200 |

3.5KW |

5-6bar |

380V |

1000±50mm |

|

|

05 |

JH-OF-14 |

0-200 |

4.5Kw |

5-6bar |

380V |

1000±50mm |

|

|

06 |

JH-OF-16 |

0-200 |

4.5Kw |

5-6bar |

380V |

1000±50mm |

|

|

07 |

JH-OF-20 |

0-200 |

5Kw |

5-6bar |

380V |

1000±50mm |