Automatic Bottled Drinking Water Filling Machine

Video

Description

Water and carbonated soft drinks are two of the most valuable beverage categories in the world. Our engineers know the liquid (water, beverage, liquor, etc.) packaging industry very well. We are proud to offer our customers a wide variety of bottled water equipment. We provide everything needed for the water filling and packing line. Whether you produce distilled water or soda water, we can help you achieve more with our solid expertise and strong packaging capabilities. Our filling equipment is manufactured in accordance with the strictest quality standards under guaranteed sanitary conditions, to provide customers with the best quality products, but also to provide customers with rich professional knowledge, production line equipment and continuous service. Ensures high quality and efficiency from packaging to equipment, ensuring that your products are stable and attractive to consumers.

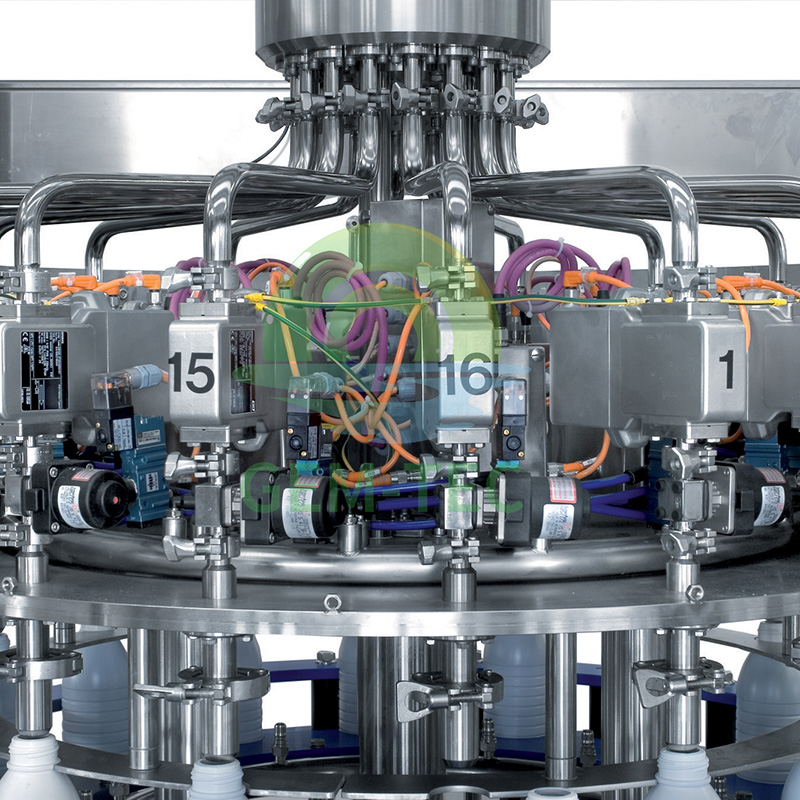

JH-LF Water filling machine is the best choice for bottle or PET bottled water filling. No matter how different the bottles are, it can adapt. In addition to filling water can also be filled with good flow, no foam of other fluids. Mechanical structure stability, high economy.

Filling technology is gravity mechanical liquid level filling: lift the bottle to open the filling valve and start filling (no bottle, no filling); When the fluid enters the return pipe, the pipe closes. The filling level depends on the positioning of the return pipe.

Of course, you can also custom measure filling products. For example: flowmeter filling or measuring cup filling mode, filling capacity is easy to adjust. You can also choose pressure filling or vacuum suction filling, which can speed up the filling speed and improve the production efficiency under the premise of ensuring the liquid level requirements.

In order to maximize the cleanliness of the water filling machine, the visible part of the water filling machine area can be washed with sterilized water. The material channel can be connected to CIP device, and the cleaning of the filling cylinder is carried out through the jet ball system. The putting and taking out of the fake cups are manual operations, and automatic cip cups can also be customized.

Features

1. Adopt Siemens control system, with high automatic control ability, all parts of the function of automatic operation, no operation after starting (such as: filling speed follow the whole line speed, liquid level detection, liquid inlet regulation, bubble pressure, lubrication system, cover conveying system);

2. The material channel can be cleaned CIP completely, and the workbench and the contact part of the bottle can be washed directly, which meets the sanitary requirements of filling; Can be used according to the need of single-sided tilt table;

3. Different diameter bottles, easy to replace the cover, strong applicability;

4. The mechanical filling valve is simple in structure, easy to maintain and easy to adjust the filling level;

5. The screw cap torque is easy to adjust;

6. Local or overall customization can be accepted for different bottles, LIDS, materials, washing requirements, filling accuracy and the cleanliness of the filling environment;

7. For customers who require accurate filling volume, electronic quantitative filling valve can also be used to change the capacity. As long as the filling speed is adjusted on the HMI, accurate switching can be achieved.

Partial Products Main Technical Parameter

| Model | Washing heads |

Filling heads |

Capping heads |

Production Capacity |

Machine Power |

Weight | Overall dimension (mm) |

| CGF8-8-3 | 8 | 8 | 3 | 2000 B/H (500ml) | 2kw | 2000kg | |

| CGF14-12-5 | 14 | 12 | 5 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| CGF18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| CGF24-24-8 | 24 | 24 | 8 | 8000B/H (500ml) | 5kw | 6500kg | 3100*2450*2300mm |

| CGF32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| CGF50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900 mm |

| GCGF60-40-15 | 60 | 40 | 15 | 24000B/H (500ml) | 15kw |