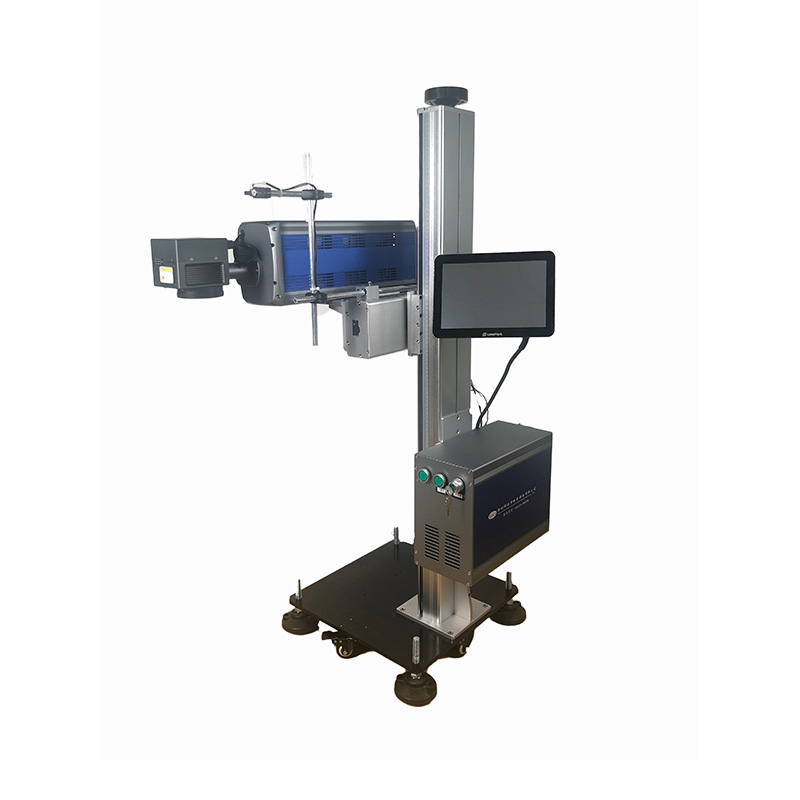

Automatic Bottle/ Can Laser Coding Machine

Description

The computer control system includes a computer and a digital galvanometer card, and the driving optical system component emits a pulsed laser according to the parameter action set by the marking control software, thereby precisely etching the content to be marked on the surface of the processed object.

Control system full English interface, compatible with AUTOCAD, CORELDRAW, PHOTOSHOP and other software output files, can be bar code, QR code, graphic text, etc., support PLT, PCX,DXF, BMP, AI and other file formats, directly Using SHX and TTF fonts, you can automatically encode and print serial numbers, batch numbers, dates, and more.

Adapting materials and industries:

Craft gifts, furniture, leather garments, advertising signs, model making, food packaging, electronic components, pharmaceutical packaging, printing plates, shell nameplates, etc.

Suitable materials are mainly non-metallic materials such as bamboo and wood products, paper, cloth leather, plexiglass, epoxy resin, acrylic, polyester resin.

Features

|

Feature |

|

| Laser engraving machine | Laser coding machine |

| Scanning galvanometer | SCANLAB |

| Focusing lens | HMKS |

| Optical path system | Standard |

| Software | Marking machine software control card |

| Work interface | Work surface *1 (small format lift) |

| Computer | Industrial Control Computer |

| Marking area | 30W-- |

| Dimensions (L* W *H) | 78cm*50cm*136cm |

| Weight (N.W.) | 78KG |

| Inclusive transportation, quality assurance for two years, installation and commissioning training | |

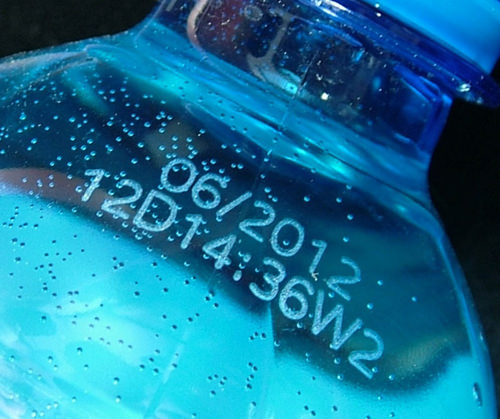

Product Effect

Data

|

No. |

Item |

Remark |

|

1 |

laser wave length | 10.6um |

|

2 |

Average laser power | 30W |

|

3 |

Modulation frequency | 20-120KHZ |

|

4 |

Marking depth | <0.2mm |

|

5 |

Maximum marking speed | 8000mm/s |

|

6 |

Minimum line width | 0.005mm |

|

7 |

Total power | 500W |

|

8 |

Marking speed | 800 character/s |

|

9 |

Galvanometer repeatability | ± 0.05mm |

|

10 |

cooling method | Air cooling by fans |

|

11 |

Beam quality | M2<1.3 |

|

12 |

Laser life | 10000hours( By Professional experimental data ) |

|

13 |

Minimum character | 0.1mm |

To those customers who are in abroad, our company will live streaming videos to provide the Technical training until the operator has reached the basic normal use of the equipment.

The main training contents are as follows:

① The training of How to use common drawing software;

② Training in the use of marking control software;

③ Training in Switching machine operating procedures;

④ The meaning of the panel and software control parameters, the training of the parameter selection range;

⑤ Basic cleaning and maintenance of the machine.

Equipment Maintenance

● The equipment is free of warrant for 24 months and is maintained for lifetime.

● Free technical consultation, software upgrades and other services.

● When the equipment warranty expires, the repair service will be provided for lifetime, and the cost will only be charged for the accessories.

● Extensive hardware and software support is available after the warranty period expires.

Part Of Clients